Back in the game with Foldarap superpowers

By Xevel on Friday, November 15 2013, 21:34 - Hacking - Permalink

Hey, long time not see. It's been a busy year. Things are moving again though :) Let's dive in!

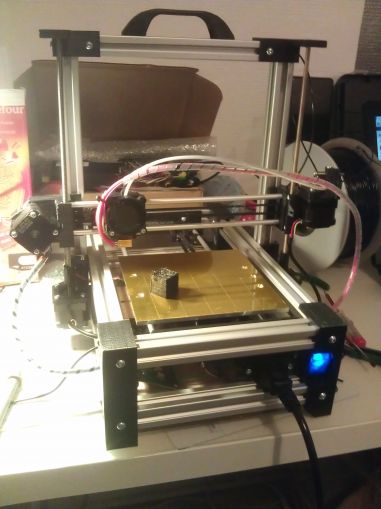

The most important news is that I am now the owner of a 3D printer, a Foldarap. It's a RepRap that has the cool feature of being foldable to the size of a briefcase. I got the "peer to peer" package of the ulule crowdfunding campaign, and had a friend print me the parts on his Solidoodle.

This printer comes as a kit that cost me 500€, plus the parts I had my friend print.

First surprise when I tried to assemble a few parts, impossible to put the aluminum profiles in the 3D printed parts... It turns out that some of the parts might have to be printed at 101% to get the proper result... I should read the instructions sometimes ^^

So instead of re-printing anything, I carved the inside of each part with a Dremel and a small end-mill. Around 3h later I had all the parts down to size.

At some point, I realized one of the parts (the one that holds the extruder motor) was not the right one, I had the old model that accommodated a geared stepper, whereas my kit had the hardware to mount an extruder with a direct drive NEMA 14. Of course, the holes did not match, I had to modify the part... but it turned out OK, I have found the proper way to tighten everything and haven't even changed it since.

The rest of the build went smoothly (well apart from when I made silly mistakes like mounting the plate that supports the bed upside down...), it's a great kit!

I started printing right away, and while the first print started very well, it turned to crap after before the end. The causes were that the temperature sensor was not mounted properly (the cable sometimes lost contact!), plus my inexperience that made me select an extruder temperature too low (190°C).

The printer itself is very stable, and as long as you feed it plastic reliably - which has been a problem until I raised the current of the extruder stepper to the suggested values and tightened the bolt on the idler... Even after traveling by train/bus/car and walking a lot, it is still perfectly ready to print as soon as I unfold it :)

Currently, I stopped using the heat bed, and put some UHU glue on it to get that damn 1st layer to stick. Now it sticks all right, maybe a little too much. Also, I now extrude at around 210°C, which gives me an awesome cohesion between layers.

I still haven't mastered it, but I get acceptable results, sometimes :p. It's a long road, but at least now I'm walking it instead of sitting on the side!